Assembly line layout services

In many industries, the term “assembly line” conjures up images of an inefficient, inflexible system of production. But in today’s competitive marketplace, that image is outdated. A new generation of assembly line layout services is providing a more flexible, efficient way to produce goods. These new services are based on the latest advances in manufacturing technology and lean principles. They allow companies to customize their assembly lines to meet their specific needs, while still providing the efficiency and cost savings of an assembly line. In this article, we will take a closer look at these new assembly line layout services and how they can benefit your company.

There are many different types of assembly line layout services available. The most common type is the conveyor belt assembly line. This type of assembly line is composed of a series of conveyor belts that move parts from one station to another. There are also robotic assembly lines, which use robots to move parts from one station to another.

After reading this article, it is clear that there are many benefits to using an assembly line layout service. This type of service can help to improve the efficiency of your assembly line, and can also help to improve the quality of your products. In addition, an assembly line layout service can also help to reduce the cost of your production.

Top services about Assembly line layout

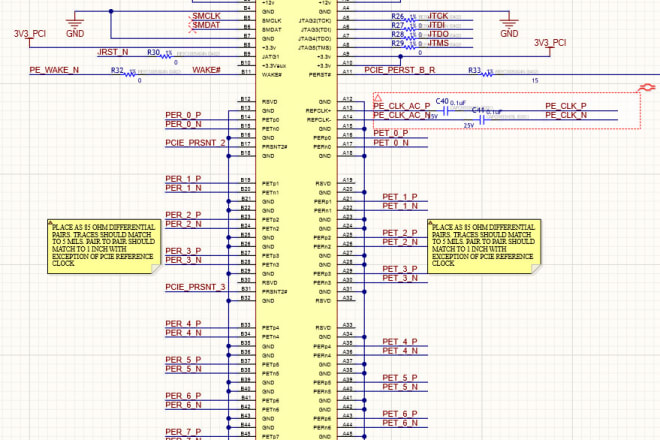

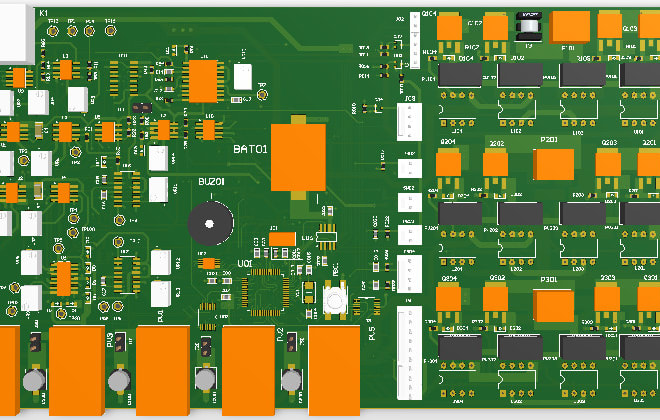

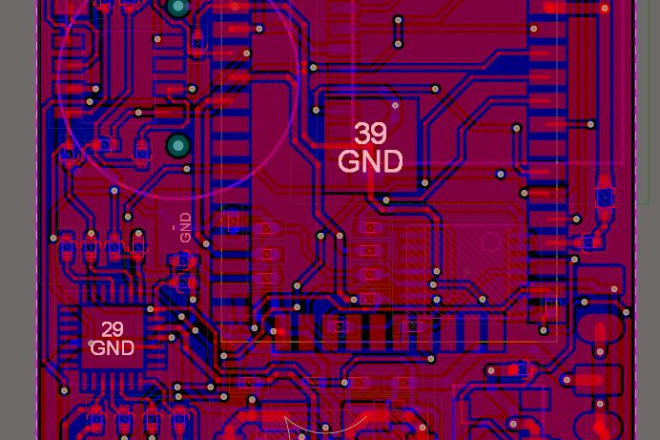

I will provide professional schematic and pcb design

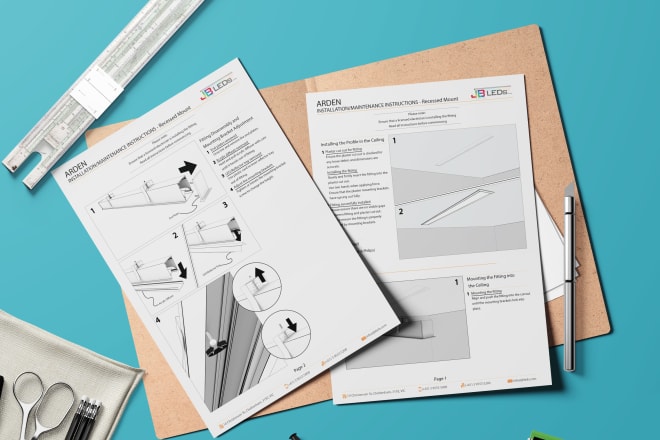

I will create a product installation or instruction guide

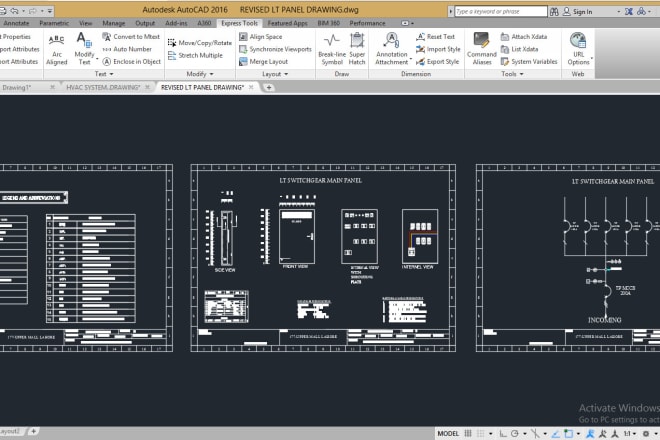

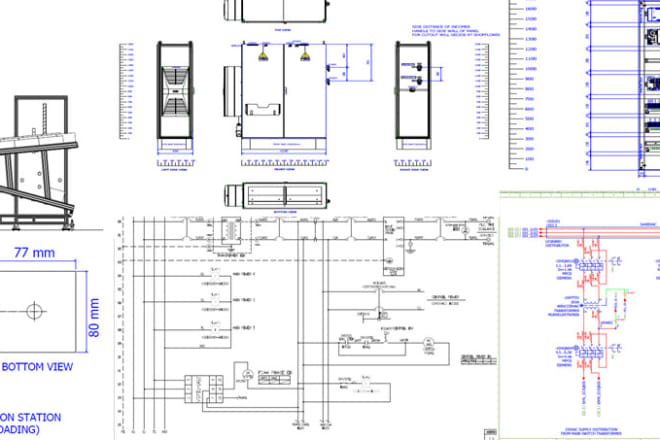

I will create electrical panels drawing,electrical designs with autocad

I will create assembly instructions user manual for your product

I will design schematic with pcb on altium and eagle

I will do pcb design and schematic

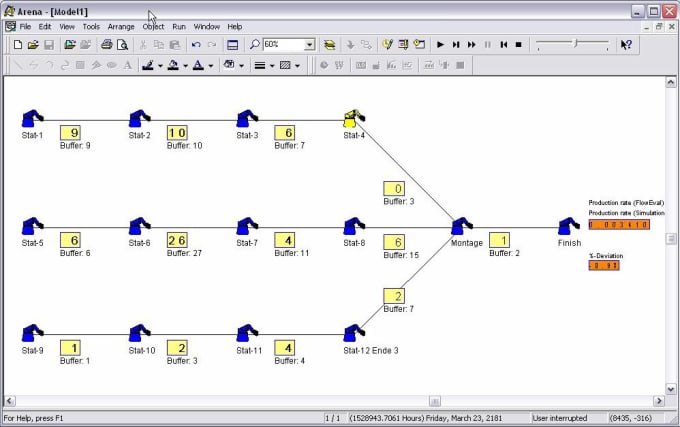

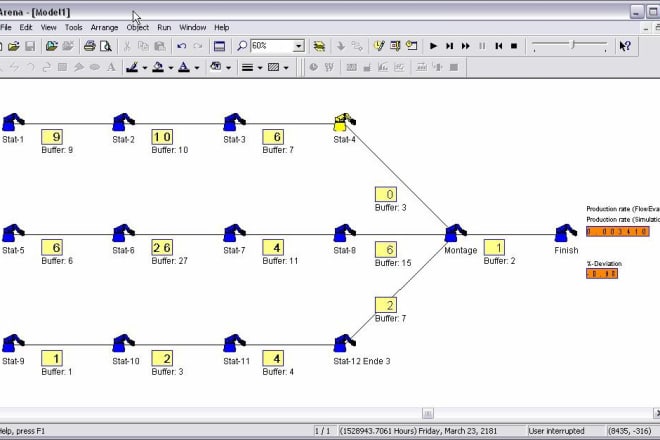

I will design, simulate and balance assembly line in arena software

I am a professional data analyzer and simulator. I will analyze and then simulate your manufacturing data and assembly line process with ARENA and Simul8 software.

It will help you to understand your project and to improve it by making the different changes required at different stages of the project.

I do

- 3D modeling

- Construction models

- Mechanical parts

- Bio medical parts

- Tools

- Surface modelling

- Assembly

Contact me before placing an order.

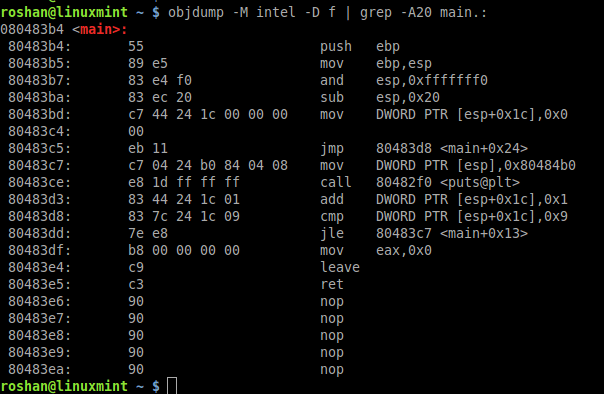

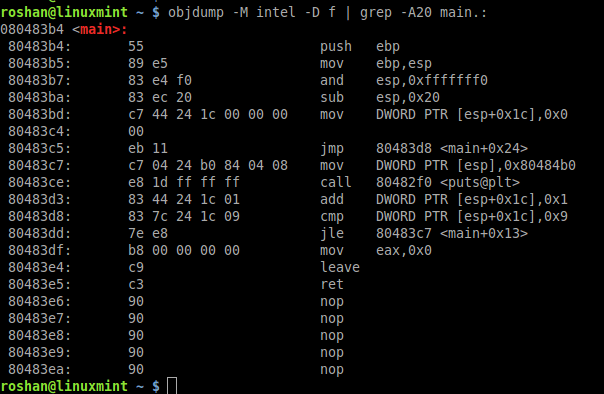

I will do x86 assembly language masm, nasm, tasm programming

I can do Microcontroller programming in assembly language for Atmel 89C51, PIC MCU, 68HC11 Microcontrollers.

I will do x86 assembly language masm, nasm, tasm programming

I will do expert work in electrical design using autocad and eplan

I will do mips, avr, arm, assembly, c plus plus tasks specially for microcontrollers

I will design, simulate and balance assembly line in arena software

I will do x86, mips, and arm assembly language projects

I will do microcontroller and microprocessor related tasks