Fea analysis solidworks services

There are many engineering and design companies that outsource their work to FEA analysis solidworks services. This is because these services have the expertise and experience to provide high quality and accurate results. In addition, they use the latest software and tools to carry out their work. As a result, they are able to save their clients time and money.

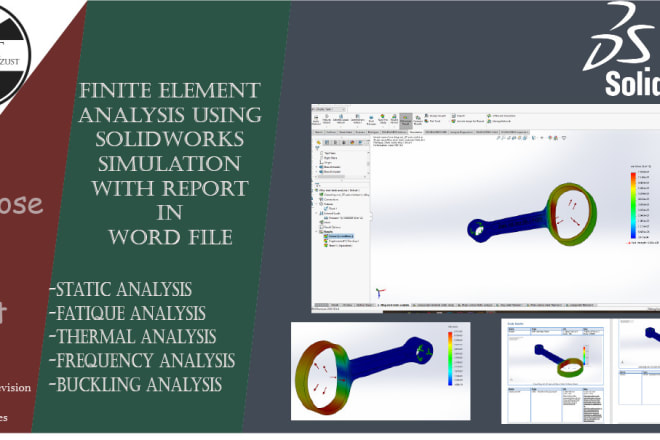

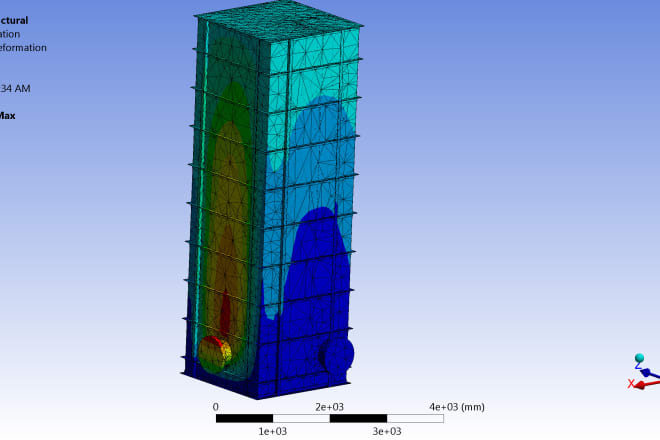

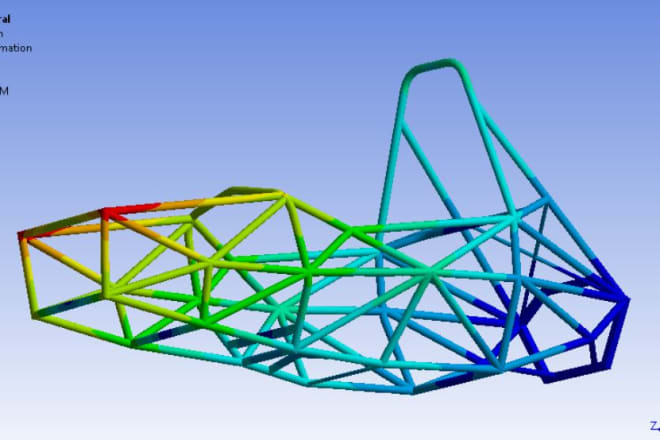

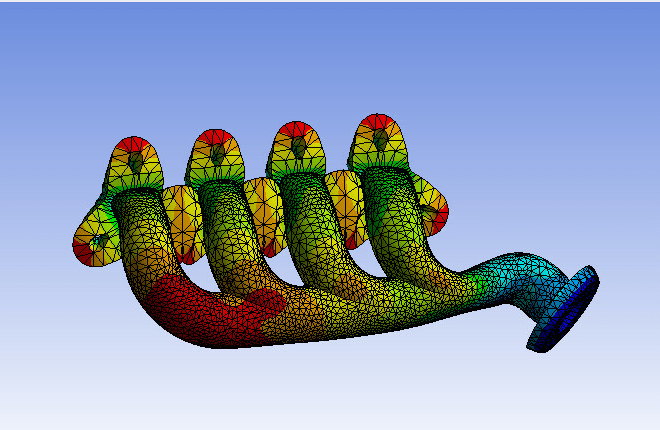

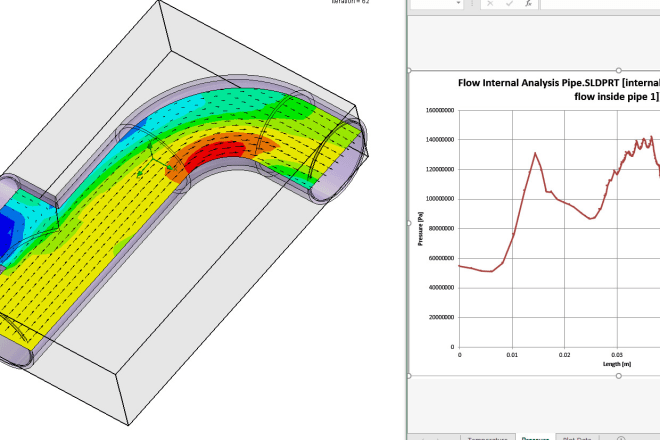

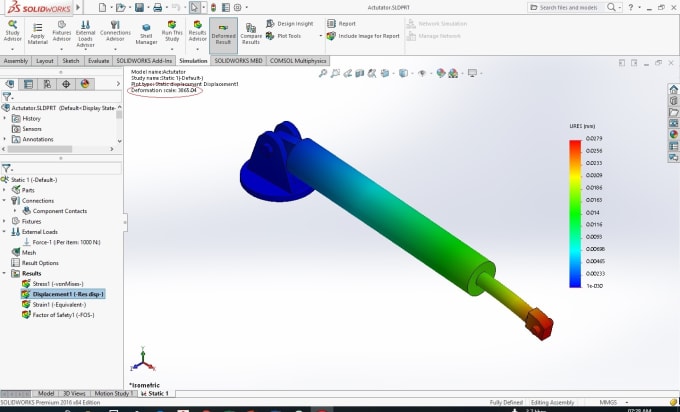

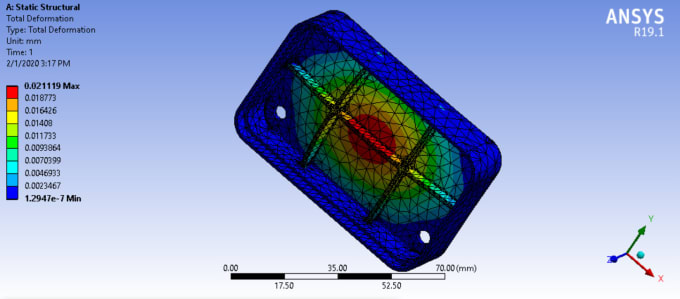

There are many different engineering analysis services that can be performed on Solidworks models. Some of the most common types of analysis that can be performed include structural analysis, thermal analysis, stress analysis, and fatigue analysis. Each type of analysis can be used to study different aspects of the model and can help engineers to understand how the model will behave in different situations.

There are many reasons to outsource your FEA analysis to a company that specializes in SolidWorks services. The most important reason is to ensure that your product is designed correctly and will function as intended. A good FEA analysis will identify potential problems with your design and help you to correct them before manufacturing. This can save you a lot of time and money in the long run. Another reason to use SolidWorks services for your FEA analysis is to take advantage of the latest software and hardware. This can make a big difference in the accuracy of the results. SolidWorks is constantly improving their software and hardware, so you can be sure that you are getting the best possible results. Finally, by outsourcing your FEA analysis to a SolidWorks services company, you can focus on your core business. This can free up your time to develop new products or improve your existing products. There are many benefits to using SolidWorks services for your FEA analysis. By using the latest software and hardware, you can be sure of getting accurate results. This can save you time and money in the long run. In addition, by outsourcing your FEA analysis, you can focus on your core business, which can improve your bottom line.

Top services about Fea analysis solidworks

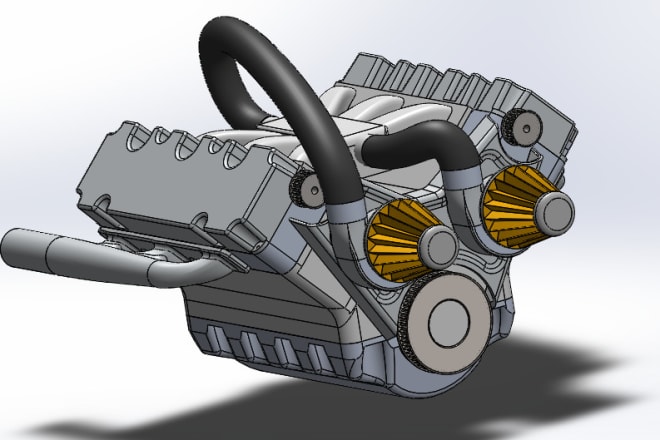

I will do fea analysis and 3d modeling using solidworks

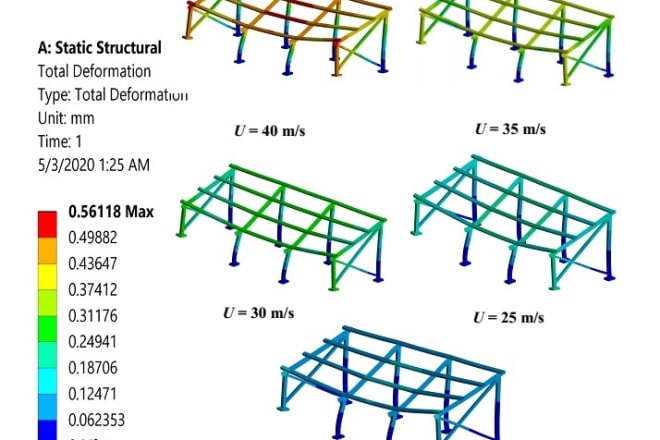

I will perform fea analysis on solidworks and ansys

I will do finite element analysis fea on solidworks and ansys

I will do fea, cfd, analysis, 3d modeling on ansys and solidworks

I will make cfd and fea analysis with ansys, comsol or solidworks

I will do solidworks 3dcad and autocad 2d drawings

I will do 3d modeling and perform fea and motion simulations etc

I will do fea analysis using solidworks and ansys

in this gig i will provide you my services related to Structural analysis

i can also model your design using solidworks and then will do simulation using ansys structural and solidworks

what is included in this gig.

- Fea usingsolidworks or ansys

- 3d modelling of your design

- unlimited revisions

- video tutorial

- source file

- full documented report of analysis

- fast delivery no delay

DO MESSAGE ME BEFORE PLACING ORDER.

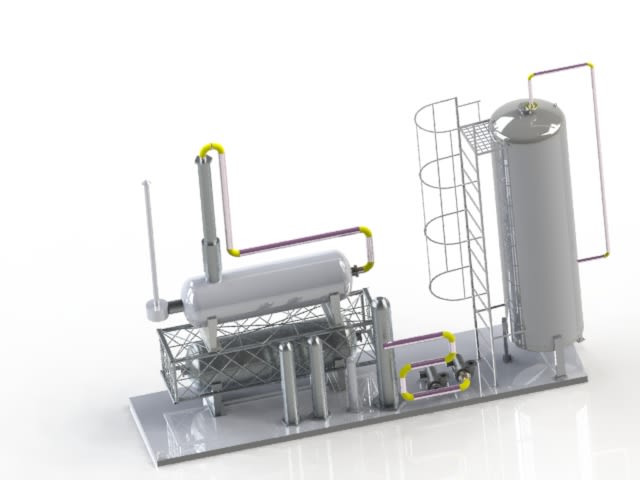

I will do 2d,3d modelling and animation in solidworks

I am ubaid ,i am a Mechanical engineer and have over 3 years of experience in making 3D models,Mechanical design and analysis using

solidworks,autocad,pro e,ansys

i offer the following services

- design 3D models using solidworks

- 3D rendering with high quality image using solidworks visualize

- 3D assemblies using solidworks

- 3D animations using solidworks

- 3D printing with checked stl files on shapeways

- simulations using soldiworks

- Make 2D drawings using solidworks

- sheet metal working ,weldments using solidworks

i will be using soildworks visualize,photoview 360 and keyshot program for rendering

Offers:

- unlimited revisions

- Quality work within the specified time frame

I will make solidworks design works for industrial projects

I will do 3d modeling and finite element analysis on ansys and solidworks