Finite element analysis ansys workbench services

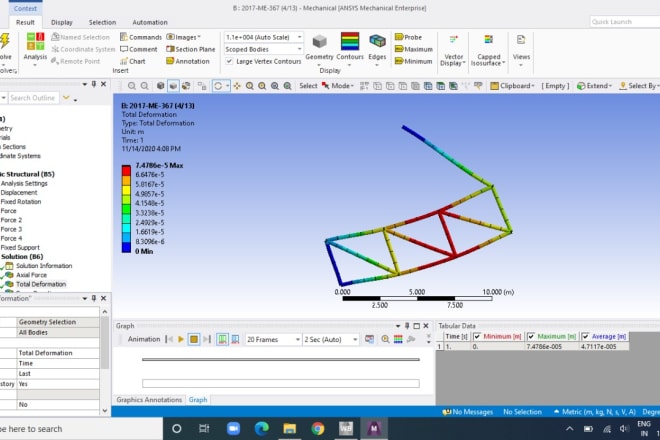

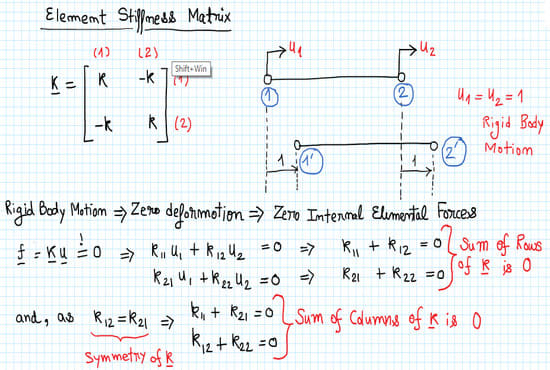

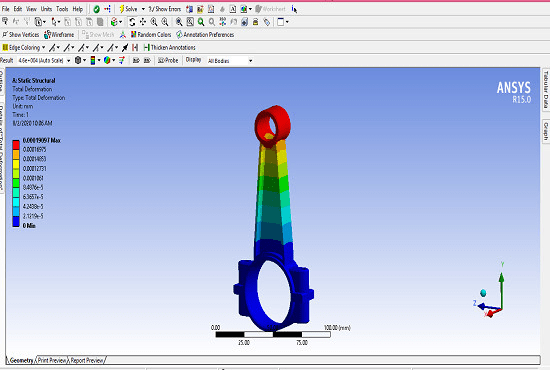

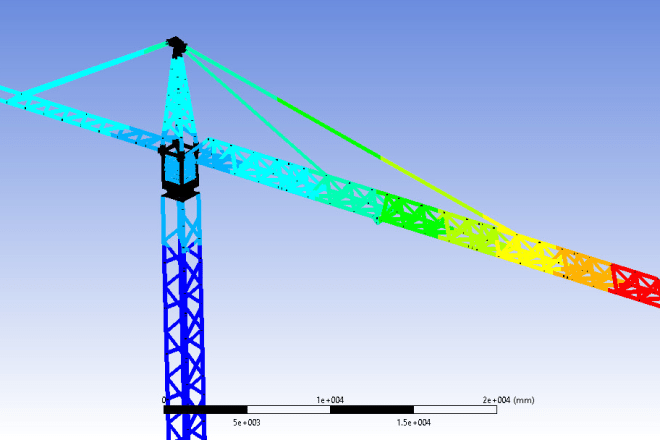

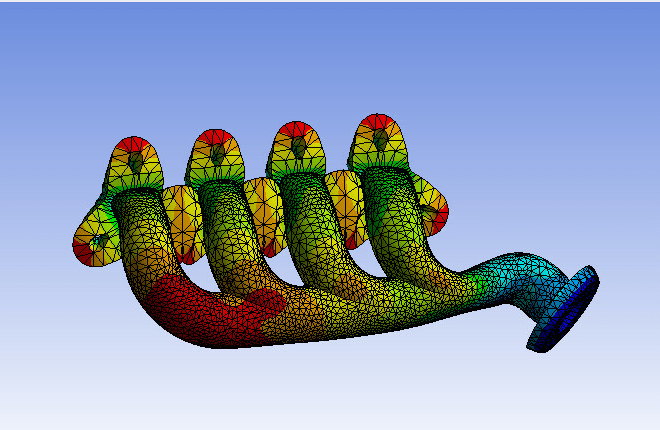

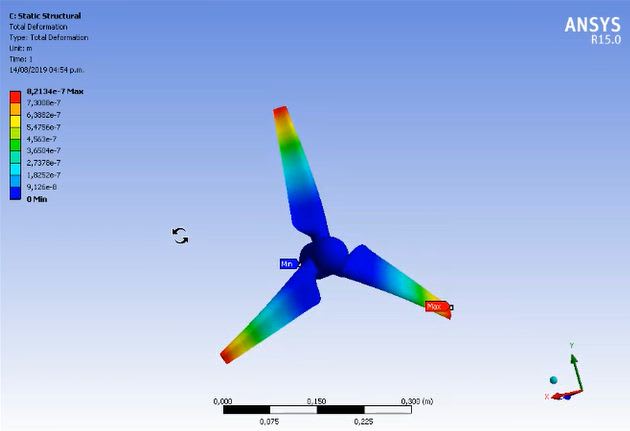

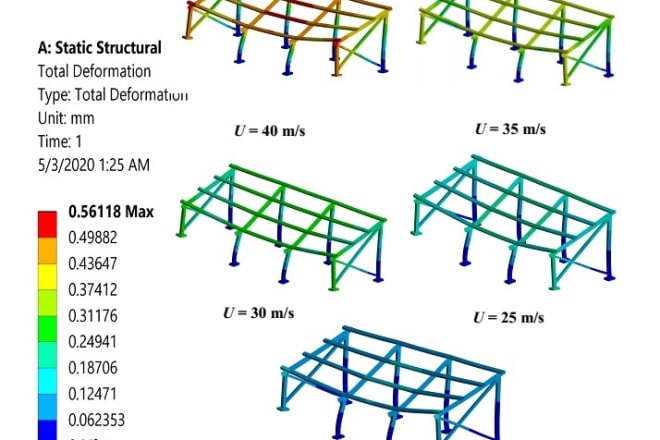

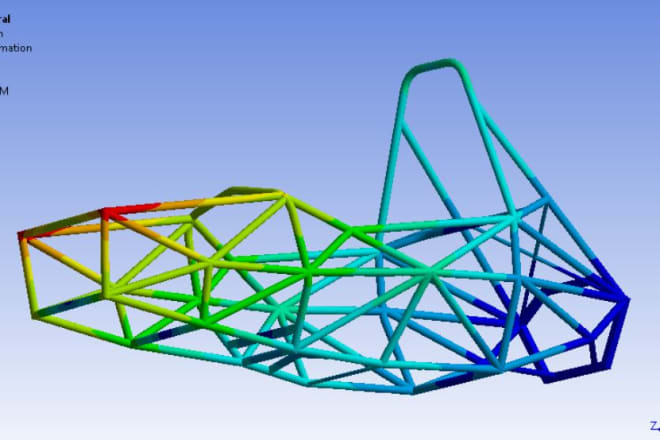

Finite element analysis (FEA) is a numerical method for solving problems in engineering and physics. The basic idea of FEA is to divide a complex problem into smaller, simpler pieces that can be solved more easily. The individual pieces are then combined to give the overall solution to the original problem. FEA is used extensively in engineering, especially in the design of mechanical and structural components. It is also used in physics, for example to study the behavior of materials under various loads. There are many software packages available for doing FEA. One of the most popular is ANSYS Workbench. ANSYS Workbench is a comprehensive suite of tools for doing FEA. It includes a wide range of features, from simple meshing and solution tools to more advanced tools for doing complex analysis. There are many service providers that offer ANSYS Workbench services. These service providers can help you with everything from setting up your model to post-processing your results.

Finite element analysis (FEA) is a numerical method for solving problems in engineering that can be modeled as a system of linear equations. FEA is used to find approximate solutions to the equations, which can then be used to design and optimize engineering systems. Ansys Workbench is a commercial software package that provides a user interface and tools for FEA. Services that use Ansys Workbench can be used to design and optimize products, structures, and processes.

There are many benefits to using finite element analysis (FEA) services, especially when it comes to engineering and manufacturing. FEA can help improve product designs, optimize manufacturing processes, and reduce costs. When it comes to engineering, FEA can help identify potential failure points and help engineers design products that are stronger and more durable. In manufacturing, FEA can be used to improve yields, reduce scrap, and improve quality. Overall, FEA is a powerful tool that can help organizations improve their products and processes.

Top services about Finite element analysis ansys workbench

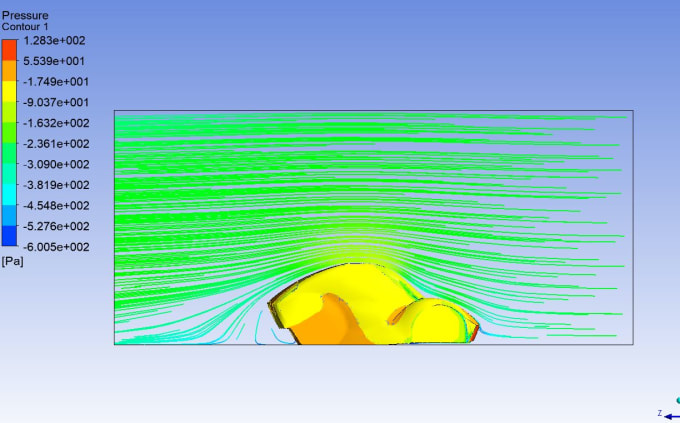

I will do aeronautical, aerospace and flight dynamics related problems

I will assist you in all relevant to finite element method and ansys

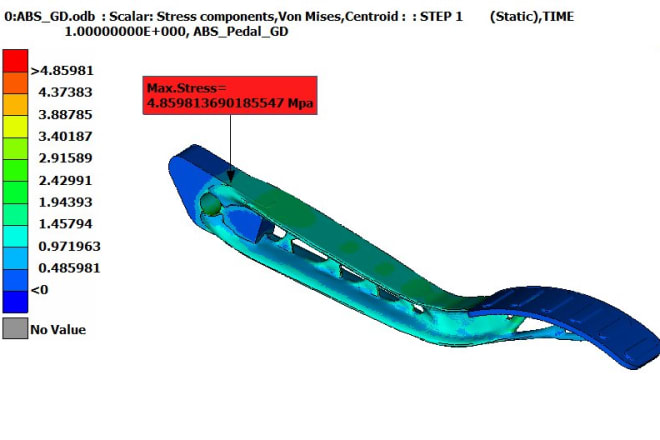

I will do finite element analysis using solidworks and ansys with reports

I will do finite element analysis fea using ansys workbench

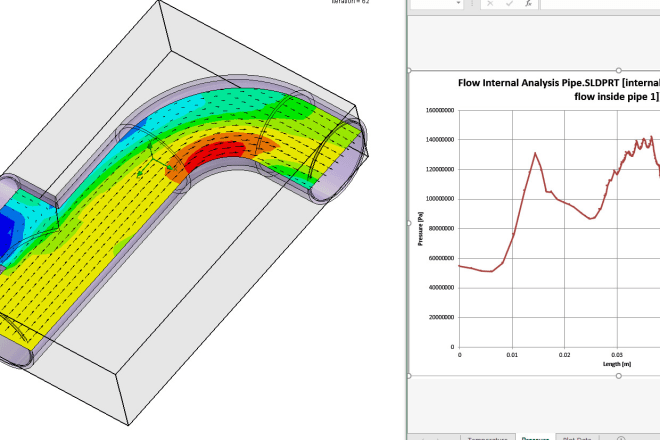

I will do fea, cfd, analysis, 3d modeling on ansys and solidworks

I will perform finite element analysis using solidworks or ansys

I will do mechanical product design

I will do 3d modeling and finite element analysis on ansys and solidworks

I will do finite element analysis fea on solidworks and ansys

I will do 3d designing and finite element analysis fea on solidworks and ansys

I will do finite element analysis for you

I will do finite element analysis

1) ANSYS

2) SOLID WORKS

i have allot of experience in the field of analysis and modelling and you will be satisfied with end result.

I will make cfd and fea analysis with ansys, comsol or solidworks

I will do cfd, fea analysis and meshing in ansys fluent