Five s program services

The "five s program services" is a system of organization and improvement implemented in many manufacturing and service organizations. The program is designed to create a clean, safe, and efficient work environment. The five s's stand for sort, set in order, shine, standardize, and sustain. The program is based on the philosophy that a well-organized workplace is a productive workplace. The program is implemented through a series of activities, including regular housekeeping, organization of work areas, and communication of standards. The program is designed to be flexible, so that it can be adapted to the specific needs of each organization. The five s program is an important part of lean manufacturing and continuous improvement. The program has been shown to improve safety, quality, and productivity. It is a simple, yet powerful, tool that can help organizations to reach their full potential.

The five s program services is a program designed to help businesses improve their operations and efficiency. The program is based on five key principles: sort, set in order, shine, standardize, and sustain. The program helps businesses to identify and eliminate waste, streamline their operations, and improve their overall performance.

The five s program services is a great way to get your company organized and improve your bottom line. The program is affordable and easy to implement. It will help you improve communication and efficiency in your workplace.

Top services about Five s program

I will build manychat bot chatbot triggered by qr code

I will build messenger chatbots for your online business

I will create a bumper set for your radio show or podcast

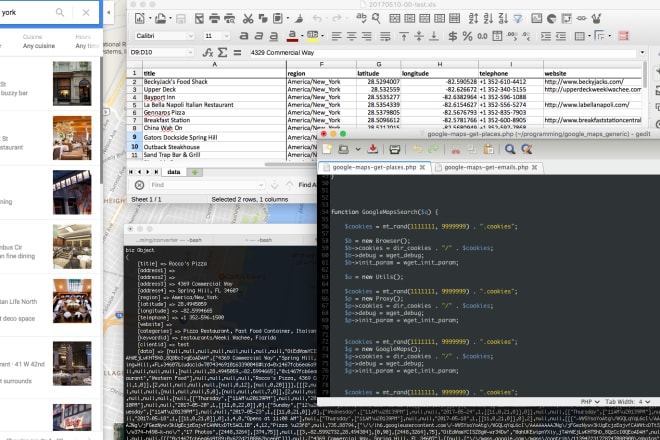

I will scrape google maps for business leads with emails

I will facetune edit and photoshop you into an instagram model

I will write SEO optimized affiliate marketing articles

I will build you a custom program or app

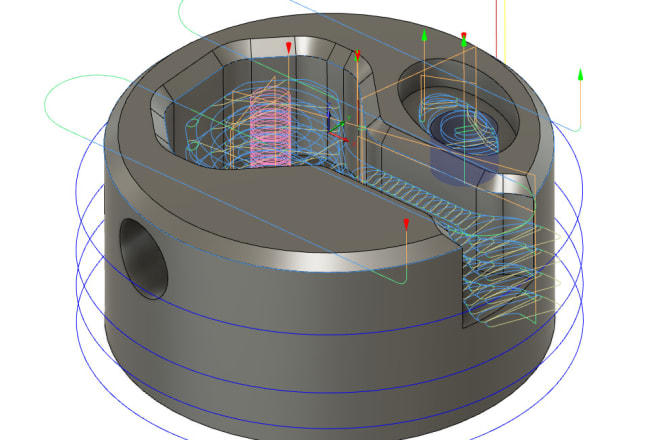

I will provide a polished cnc program for various machines

I will program an aurdino or 8051 micro controller for you

I will sell you a 7months full planche gymnastic calisthenics program

I will program a webbot or webscraper

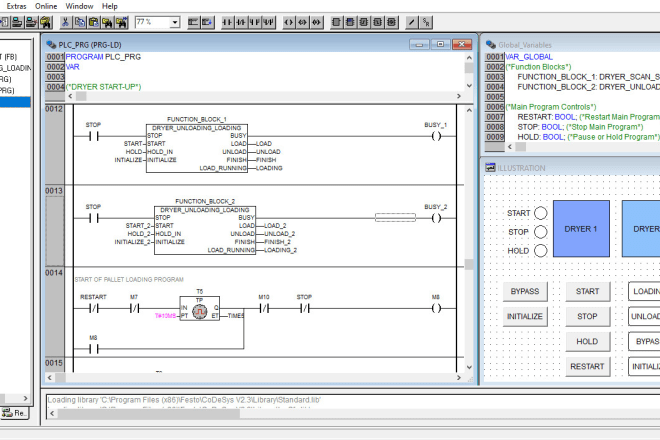

I will create a plc program for you using sysmac studio or codesys

I will create and setup your own affiliate program for your website or store

I will design a personal exercise program for you

I will sell kick start your coaching program new now with resale resell rights