Packaging line layout services

In many businesses, product packaging is a key part of the product development and manufacturing process. An efficient packaging line layout can save time and money, while a poorly designed one can lead to delays and production problems. There are many factors to consider when designing a packaging line layout, including the type of products being packaged, the packaging materials and equipment available, and the workflow of the packaging process. An experienced packaging line layout service can help businesses design an efficient and effective packaging line layout that meets their specific needs. The right packaging line layout can help businesses improve their production efficiency and quality, while reducing costs.

A packaging line layout is the design of how a packaging line will be set up. This can include machines, conveyors, and other equipment needed for the packaging process. A good packaging line layout will be designed to increase efficiency and productivity while minimizing downtime and waste.

Packaging line layout services can help you save time and money by optimizing your packaging line for maximum efficiency. By working with an experienced packaging line layout consultant, you can ensure that your packaging line is designed for your specific needs and that it meets all of your regulatory requirements.

Top services about Packaging line layout

I will do formatting and layout of ebook and printbook

I will layout your children books and textbooks in amazon KDP and ingramspark

I will proofread copy edit your document

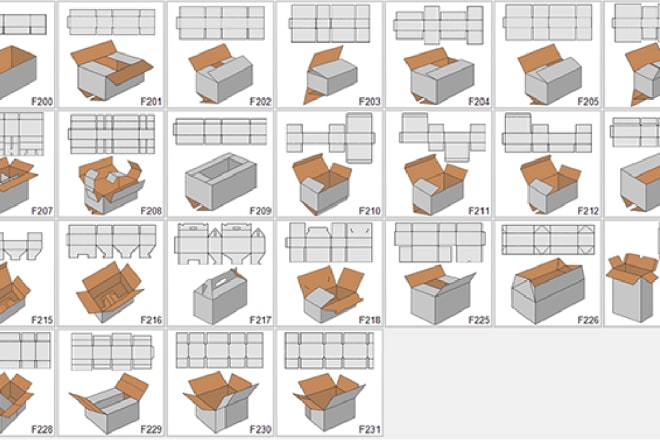

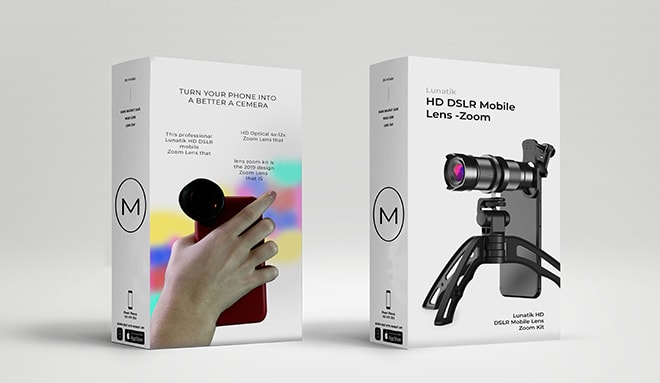

I will design product box, bag packaging, label, die cut layout

I will edit your writing to a professional and publishable standard

I will design packaging box with dieline

I will provide keylines of packaging or carton box

I will design your packaging layout

I will do any packaging box and layout design in 24 hour

I will do packaging box keylines,die layout

I will do packaging for any product

I will create 3d product packaging design in 24hrs

I will create your product label and packaging

100% Satisfiction

100% Money Back Guarantee

100% Unique Design

100% Quality Works

100% Satisfied Buyers.

What you will get in this gig:

1. Standard Package:

In this Package you will get a perfect packaging design as per your requirements..

Only JPEG and PDF file. you must have die line or template of your Packaging box etc..

If you want to need die line or template from me, I can create template of your Packaging Box Extra Charges...

2. Premium Package:

In this Package you will get an Outstanding Subscription Box or your design including:

Source File

Commercial Use

Print Ready File

Die Line / Template

Platinum Package

Awesome Design of your Products and Branding

All in one Package..

1. Awesome packaging

2. Print Ready Source file

3. Die Line / Template

4. Commercial USE

5. 3D Image View

6. Life Time Support

7. Quick Response

I will product packaging design and box design