Qa qc plan for construction services

A quality assurance (QA) plan is a document that details the processes and procedures that will be followed to ensure the quality of a project. A quality control (QC) plan is a document that details the processes and procedures that will be followed to ensure the quality of the products or services being provided. The QA/QC plan for construction services should include the following: 1. A description of the quality assurance and quality control procedures that will be followed during the project. 2. The responsibilities of the project manager, quality assurance manager, and quality control manager. 3. The procedures that will be used to monitor the quality of the work. 4. The procedures that will be used to investigate and correct quality problems. 5. The procedures that will be used to prevent quality problems from occurring. 6. The Quality Assurance/Quality Control Plan should be reviewed and updated as necessary to reflect the changing needs of the project.

There is no one-size-fits-all answer to this question, as the QA/QC plan for construction services will vary depending on the specific project requirements. However, some common elements that should be included in such a plan are quality control procedures, quality assurance objectives, and a mechanism for monitoring and reporting progress.

The QC Plan is a critical part of any construction project, as it ensures that the project meets all quality standards. By following a QC Plan, construction companies can avoid costly mistakes and deliver a finished product that meets all customer expectations.

Top services about Qa qc plan for construction

I will provide quality control and quality assurance services

I will prepare quality and safety management plan for the projects

I will provide all kind of construction management solutions

I will provide QA qc plan for construction project

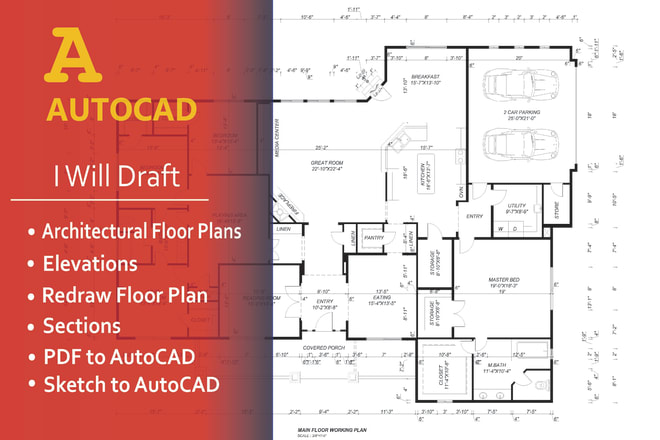

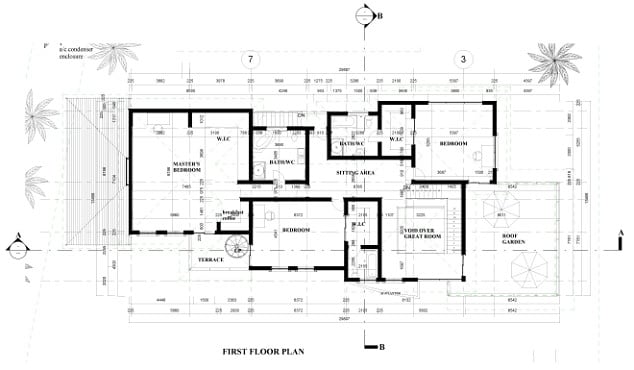

I will do your construction drawing and house plans

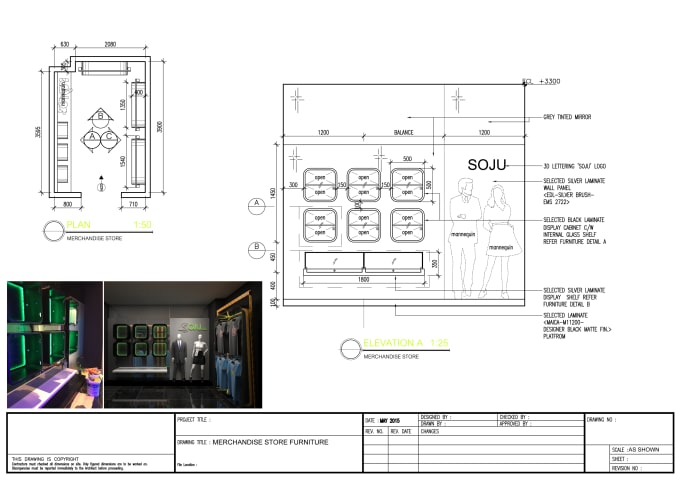

I will produce acad drawing for interior projects

The development/ shop/ construction drawings I produce includes :

- Builder's work plan

- Furniture layout plan

- Reflected ceiling plan

- M&E plan

- Floor finishes plan

- Wall finishes plan

- Elevations

- Sections

- Detail drawing (custom made furniture to interior structure)

All you need to provide me is

- Sketches

- 3D concept photo (if have any)

- Dimensions of as actual site or furnture

I have 7 years experience working as an interior designer with a construction company. I specialize in producing construction drawing from 3d concept photo for interior design project.

**Please feel free to contact me anytime before you order. Thank you!

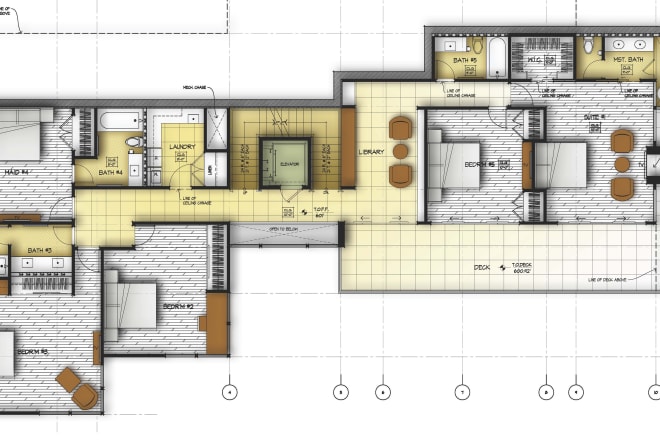

I will design architectural 2d floor plan, 3d floor plan on autocad

I will draw all professional architectural drawings

I will draw any kind of construction drawings electrical plumbing

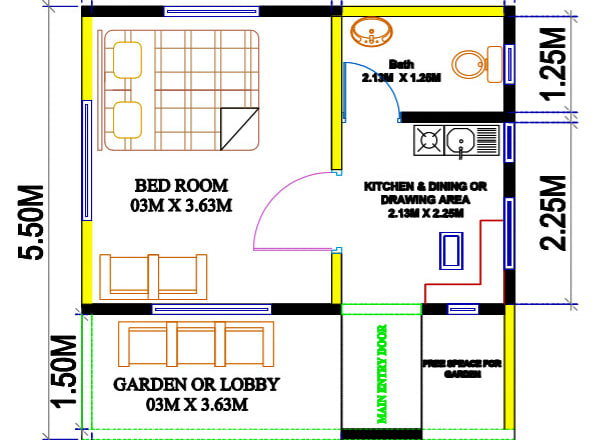

I will best 2d floor plan for you

I will create architecture floor plans, 3d floor plan 2d floor plan

I will draw floor plan, construction plan, in chief architect

I will design architectural floor plan and construction 2d floor plans, in auto cad