Solidworks scan to 3d stl services

Additive manufacturing, popularly known as 3D printing, is a process of making a three-dimensional solid object from a digital file. The creation of a 3D printed object is achieved using additive processes, where an object is created by successively adding material layer by layer. 3D printing is the opposite of subtractive manufacturing, which involves taking away material from a solid block to create an object. 3D printing has been around for decades, but has only recently become more widely available and affordable due to advances in technology. One of the most popular 3D printing processes is stereolithography (SLA), which uses a laser to cure layers of photosensitive resin. There are many different file formats that can be used for 3D printing, but the most common format is STL. STL files can be created from 3D CAD files or scanned objects. Once an STL file is created, it can be sent to a 3D printer for printing. There are many companies that offer solidworks scan to 3D STL services. These companies can take a 3D CAD file or scan an object and create an STL file that can be used for 3D printing.

There are a few companies that offer solidworks scan to 3d stl services. These companies use 3d scanners to scan your object and then create a 3d stl file that can be used in Solidworks. This is a great way to create a 3d model of an object if you do not have a 3d model already.

Overall, using a solidworks scan to 3d stl service can be a great way to get high-quality, accurate 3d models of objects. There are a few things to keep in mind when choosing a service, such as price, turnaround time, and accuracy, but overall, this can be a great option for getting 3d models of objects.

Top services about Solidworks scan to 3d stl

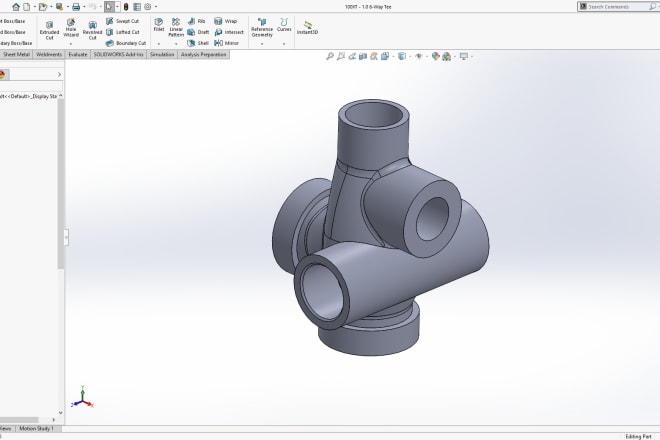

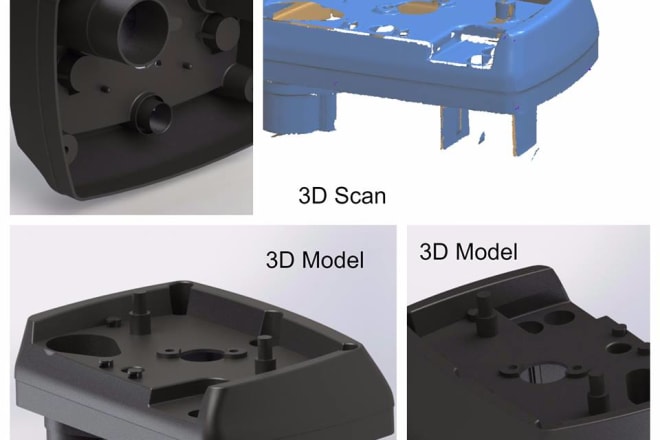

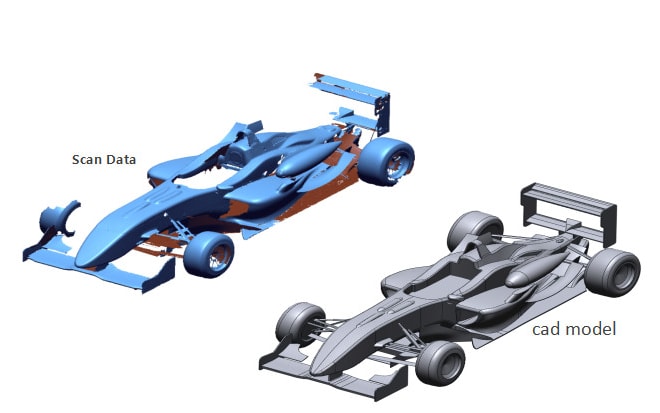

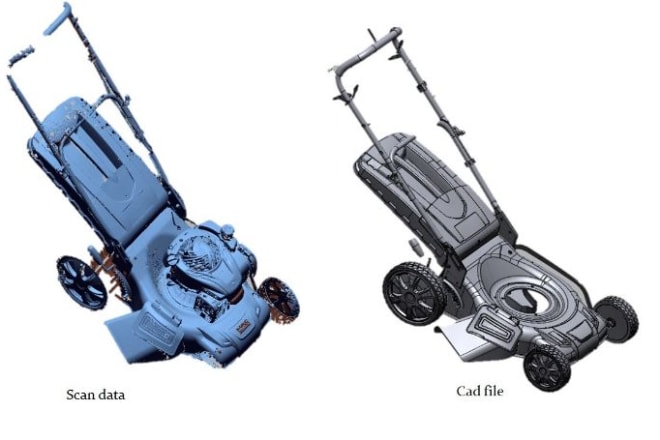

I will convert stl file or 3d scanning into cad model

I will 3d scan and model or reverse engineer any part you send me

I will reverse engineer, 3d model, 3d scan, 3d print, solidworks

I will do reverse engineering and 3d modelling from stl or obj or ptc

I will do reverse engineering on 3d scan data or point cloud data

I will do reverse engineering, designing cad model from obj, stl, 3d scan and 3d pdf

I will do reverse engineering from 3d scan, stl,pointcloud

I will do reverse engineering and 3d cad modelling

I will do solidworks 3dcad and autocad 2d drawings

I will do 2d,3d modelling and animation in solidworks

I am ubaid ,i am a Mechanical engineer and have over 3 years of experience in making 3D models,Mechanical design and analysis using

solidworks,autocad,pro e,ansys

i offer the following services

- design 3D models using solidworks

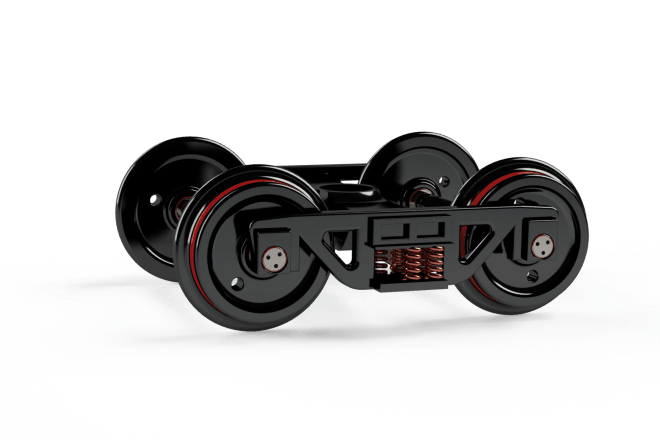

- 3D rendering with high quality image using solidworks visualize

- 3D assemblies using solidworks

- 3D animations using solidworks

- 3D printing with checked stl files on shapeways

- simulations using soldiworks

- Make 2D drawings using solidworks

- sheet metal working ,weldments using solidworks

i will be using soildworks visualize,photoview 360 and keyshot program for rendering

Offers:

- unlimited revisions

- Quality work within the specified time frame

I will teach you solidworks and autocad

I will create 3d design of any product on solidworks

Following are some 3D design Softwares I have currently available:

- Solidworks 2017

- Solidworks 2018

- Solidworks 2019

- Solidworks 2020

- Autodesk Inventor 2017

- Sketch up 2020

I can combine the best capabilities of these softwares to provide you the following services:

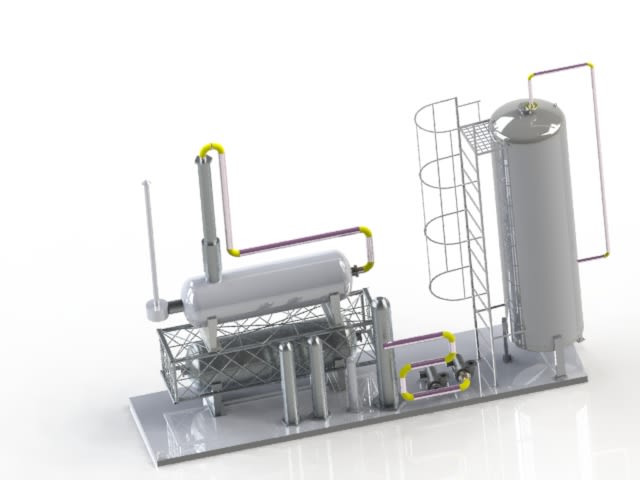

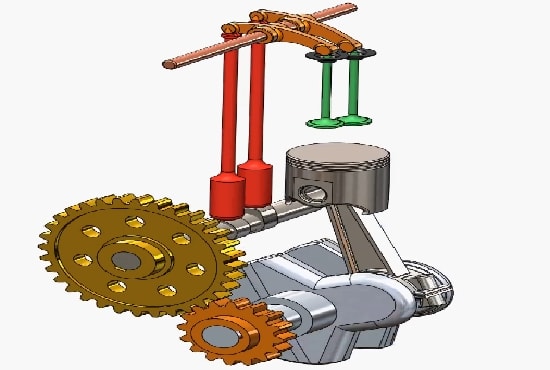

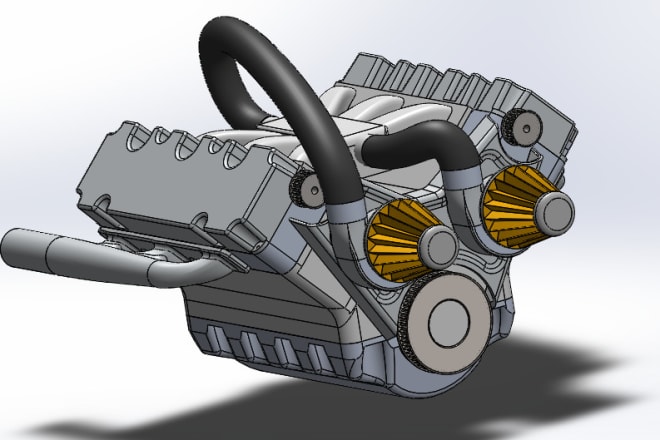

- Machine Design

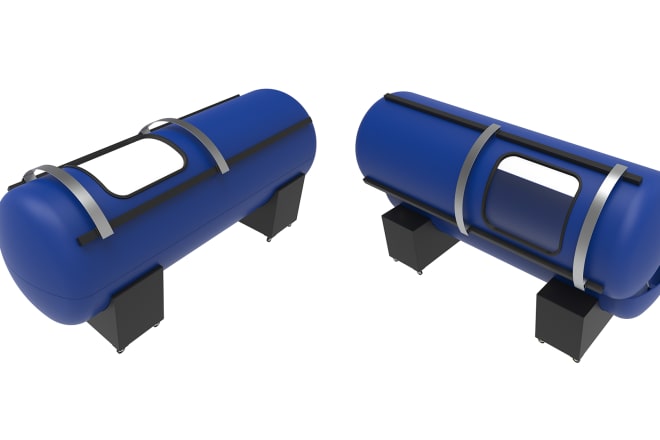

- Consumer Product Design

- Prototype Design

- 3D modeling for 3D printing

- 3D CAD

- 2D CAD

- Engineering/Manufacturing drawings.

- Linkage Mechanism Design

- 3D Animation

- 3D Rendering

I have the ability to work under the given time, resource and design constrains. Machine design in Solidworks is my specialty. For any employer who wants the task to be completed quickly and successfully, these skills would surely be an asset.

I will do solidworks 3d modeling and 2d drawing

I will create 3d model and 2d drawing using solidworks

I will make solidworks design works for industrial projects

I will do 2d,3d modelling and animation in solidworks

I will make 3d models using solidworks, fusion 360 and PTC creo

I have experience on various projects which can be provided later on demand.

I am capable of modelling complex geometries and assemblies using solidworks.

please feel free to contact me.

thanks

Zohaib