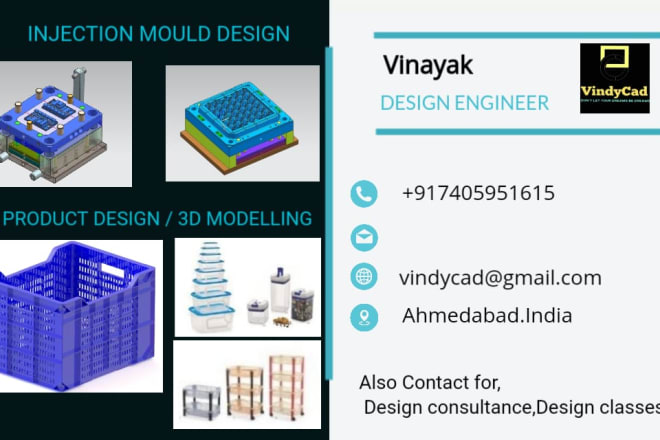

Injection mould tool design jobs services

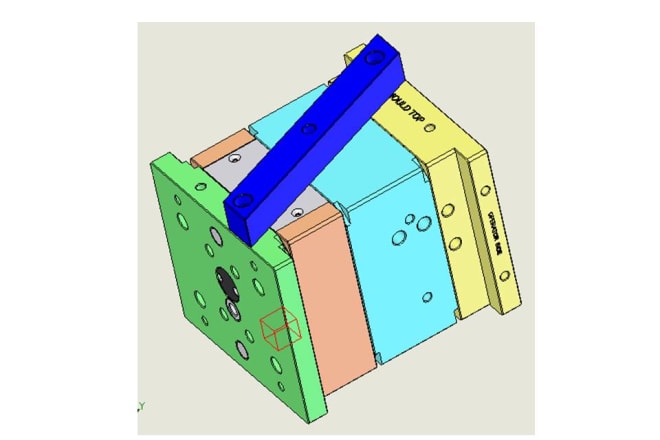

Injection mould tool design is a process of designing and creating molds for plastic injection molding. This process is vital to the manufacturing industry, as it allows for the mass production of plastic parts and products. Injection mould tool design jobs are in high demand due to the increasing popularity of plastic injection molding. There are many service providers that offer injection mould tool design services, which can be used by businesses to create custom molds for their products.

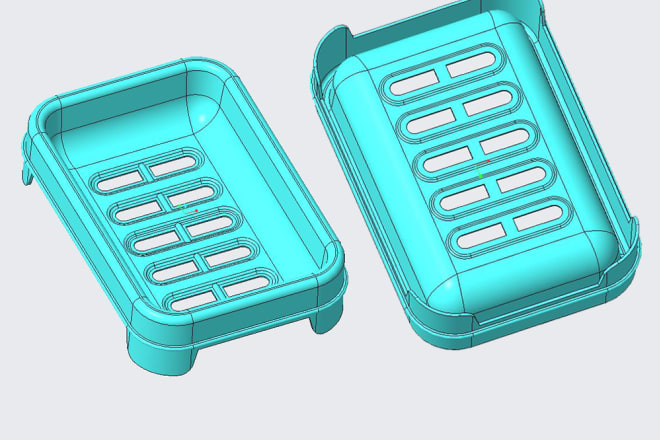

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. Injection molding can be performed with a wide variety of materials, including metals, elastomers, and thermoplastics. The material for the part is fed into a heated barrel, mixed, and forced into a mold cavity where it cools and hardens to the configuration of the cavity.

Injection mould tool design is a vital service for many businesses, as it allows them to create products that are both functional and aesthetic. There are many companies that offer this service, and it is important to choose one that is reputable and has a good track record. Designing an injection mould tool can be a complex process, and it is important to have a company that is experienced and has a good understanding of the process.

Top services about Injection mould tool design jobs

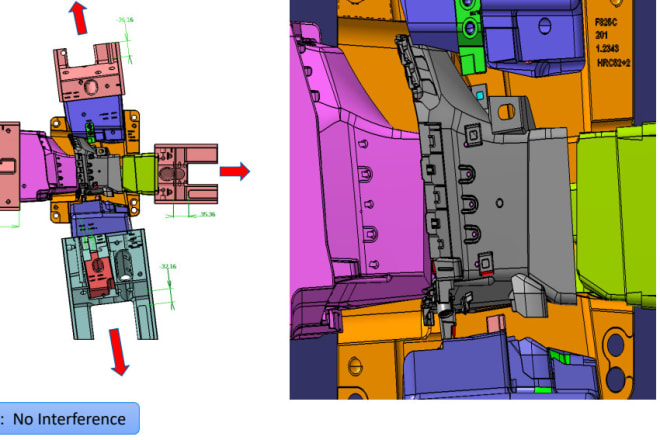

I will do tool design 2d detailing and electrode design

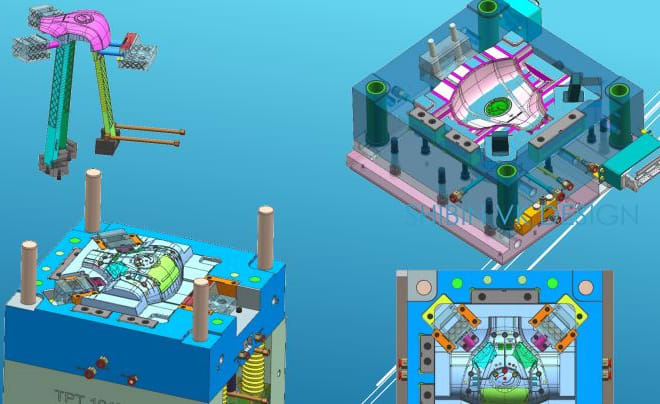

I will do injection mold design and production of plastic parts

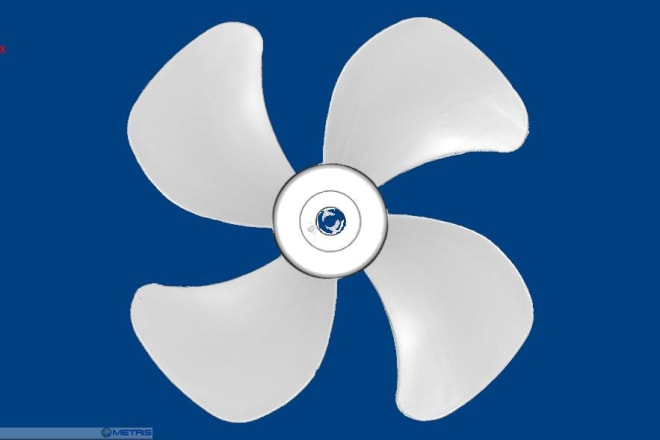

I will design plastic injection mould and silicon mold

I will design plastic injection mould designs

I will design injection molding tool

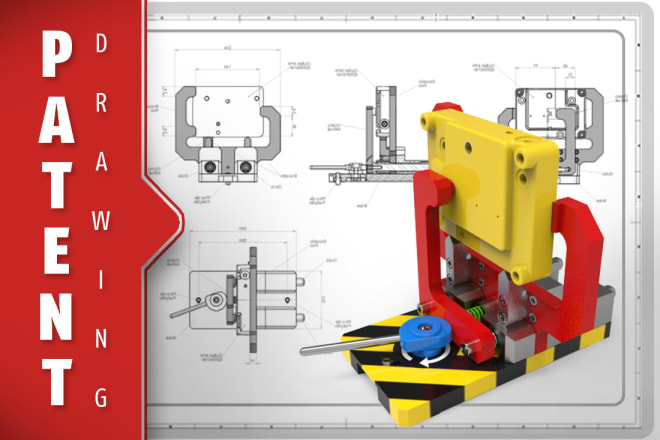

I will create 3d models and 2d drawings with solidworks for cad invent patent product

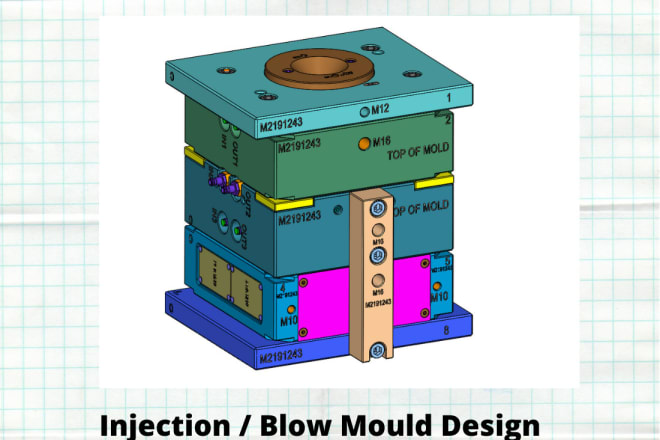

I will do mold design and create detail drawings

I will design mould mold for plastic injection component and do 3d modeling

I will do injection mould design or blow mould design and mold design drawings

I will do injection mould design

I will create standard 3d model for 3d printing, mould and cnc

I will create 3d model for 3d printing, mould injection and cnc